The Application of Measuring Instruments In The Water Industry |

| The water and wastewater industry is an important aspect of modern society, providing millions of people with safe and clean drinking water while also processing and disposing of wastewater in an environmentally friendly manner. Instruments like pressure gauges and thermometers are significantly used in the water and wastewater industries to measure, monitor, and regulate numerous parameters during the treatment process. This is due to the fact that water and wastewater treatment plants must follow tight regulatory criteria for safety, efficiency, and environmental effect. Indeed, it is critical in assisting the industry in meeting these objectives. Measuring instruments are used in a range of applications in the water and wastewater industries, including: |

Level monitoring In water and wastewater treatment systems, these instruments are used to regulate the amounts of gas or liquid in tanks, pipes, or silos. Because these pipes are typically opaque and difficult to access, visual observations cannot be used to determine the amount of gas or liquid present. |

Flow monitoring Flow instruments are fitted in water and wastewater treatment pipelines to measure the amount and rate of fluid or gas movement within an enclosed vessel. These instruments are designed to take regular measurements of volume and mass, allowing operators to monitor flow volume and mass flow to verify the safety and functionality of their equipment. |

Pressure monitoring Pressure gauges are used in pump and valve systems to monitor water pressure. Operators can ensure that pumps and valves are working properly by monitoring the pressure and adjusting the system as needed to maintain the optimum pressure. |

Filtration monitoring Pressure gauges are used to monitor the pressure of water as it travels through filtration systems. This data is crucial for verifying that the filters are functioning properly and that the water is adequately treated. |

Temperature monitoring Temperature measurement is crucial in water treatment procedures because it impacts chemical and biological responses. In the water industry, thermometers are commonly used to monitor and control temperature levels in water treatment systems. | Measuring instruments play an important part in the water and wastewater industries. Operators would have no way of knowing how the system is working without accurate measurements, resulting in inefficiencies, safety risks, and potential environmental harm. These gauges and accessories assist operators to make informed decisions regarding system operation and maintenance by providing crucial information about pressure, level, flow, and temperature, ensuring that water and wastewater systems operate at optimal levels. When choosing an instrument for use in the water and wastewater industries, it is critical to find one that is specifically developed for this kind of application. Measuring instruments developed for other sectors may be unable to endure the extreme conditions and corrosive fluids found in water and wastewater systems. It is also critical to choose a gauge that has been properly calibrated and maintained to ensure accurate readings and dependable functioning. At Floyd Australia, we offer a range of measuring instruments, as well as calibration services, which are the most common products and services being offered in the water market. Here, we provide some details about our available water pressure gauges. |

|

| Industrial Water Pressure Gauges - Specifically designed to meet the stringent demands of any industrial application

- Suitable for all applications where accuracy, repeatability, and long-term stability are of importance

- Used for liquid or gaseous substances within non-corrosive applications where the medium will not attack brass or bronze

- Suited to harsh environmental conditions

- Stainless steel case can be supplied dry or liquid-filled when protection is required against pulsation and or vibration

- Standard scales are offered in either single-scale kPa or dual kPa/PSI

- Can be modified with different scales, colored sectors, purpose wording, logos, and red lines

|

|

| Heavy Duty Water Pressure Gauges - Suitable for corrosive applications where the medium will not attack stainless steel

- Suited to harsh environmental conditions

- Stainless steel construction can be supplied dry or if protection is required against pulsation and or vibration

- Can be supplied liquid filled

|

|

|

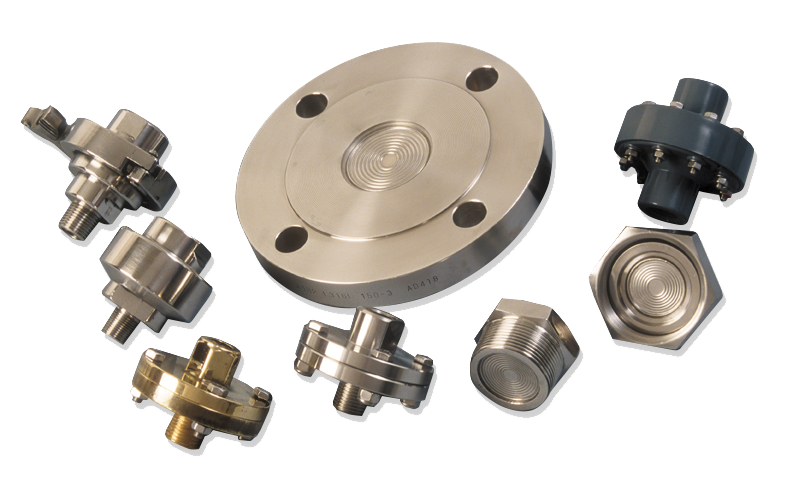

Diaphragm Seals - Used on corrosive and non-corrosive applications, where the medium may contain solids or solidify which would cause the normal bourdon tubes to be blocked and unserviceable

- Diaphragm seals can be fitted to a vast array of pressure/vacuum gauges

- The normal working temperature of diaphragm seals is 0-100 Degrees Celsius

- Temperature can be rated as high as 300 Degrees Celsius when filled with HT silicone oil and the gauge separated from the diaphragm seal using an extended neck or capillary tubing

|

|

| Differential Pressure Gauge - All stainless steel construction in 100mm and 160mm dial sizes

- Differential pressure ranges from 0-2.5 kPa up to 0-2500 kPa with maximum static pressures up to 1000 Bar

- Can also be offered with electrical contacts and diaphragm seals when the medium contains solids

|

|

| Schaffer Pressure Gauge - Designed for many applications and are an accepted standard throughout the industry.

- The more common uses are for tank content, reading of low pressures on a wet medium where a capsule gauge is unsuitable, or on mediums that contain solids that would block a normal bourdon tube gauge.

- Suitable for working temperatures up to 100 degrees Celcius

|

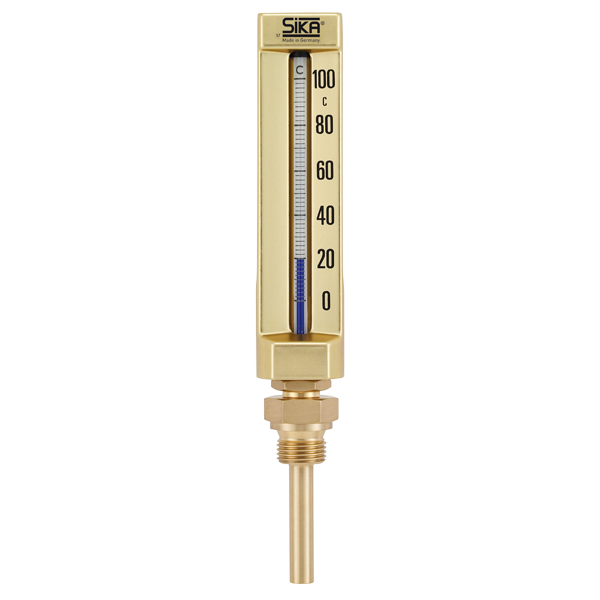

|  | Machine Glass Thermometers - Robust, reliable, and accurate

- Essential in marine, mechanical, and plant engineering

- Used in heating and air conditioning technology

- No mechanically moving part, material fatigue, and electrical energy requirement

- Long service life

|

|

| Bimetal Thermometers - Made from stainless steel

- Corrosion-resistant, can withstand rust/chemical attacks

- Great for tough industrial use

- Stem, plug, and connection of bimetallic are fused together and sealed

- Hermetically sealed

- Temperature ranges from -50°C to 550°C

- Stem lengths are from 63mm to 2metres

|

|  | Remote Reading Thermometers - Used for general industrial applications

- Ranges from -50°C up to 600°C

- Stainless steel sensing element and connections

- Robust construction

- Distance reading with 316 stainless steel capillary, lengths up to 50 meters

- Liquid filling, electrical contacts, stainless steel armoring, and thermowell available

|

|

| Type E2, D2 & C2 Digital Pressure Gauge Digital pressure gauges are particularly suitable for both stationary and mobile measurement and display of pressure. They can be used as reference pressure gauges to simplify the checking, adjustment, and calibration of other pressure measurement devices directly on-site. - Exact and reliable measurement

- Type E2 - Accuracy +/-0.5% Full Scale

- Type D2 - Accuracy +/-0.1% Full Scale

- Type C2 - Accuracy +/-0.05% Full Scale

- Easy and clear readout

- Easy to assemble and use

- 1/4 BSPP Bottom Process Connection

- EX-version available on request

|

|

| XP2i Digital Test Gauge The 2nd generation XP2i is a very rugged, intrinsically safe, digital pressure gauge with 0.1% of reading accuracy. - New nickel-plated aluminum enclosure is sealed to IP67 (waterproof to 1 meter)

- Backlight is twice as bright, but batteries last just as long

- 10% larger LCD window for a larger viewing angle

- Internal pressure is equalized by a GORE-TEX® filter

- All XP2i gauges are now CSA, IECEx, and ATEX certified intrinsically safe

- Captures open and reseat values for Pressure Safety Valve (PSV) testing

- Optional pressure data logging capability

- Torque and force measurement capable

- Simple to use

|

|

| Data Logger XP Software - In tandem with the XP2i digital pressure gauge with a purchased DataLoggerXP firmware upgrade, forms an integrated data-logging solution by collecting, saving, and transferring data to a Microsoft Excel spreadsheet.

- Long battery life, you can record up to 6000 pressure measurements for two months, without the need for external power supplies or battery replacements.

- Can measure vacuum, you can even capture pressure to vacuum transitions and much more.

- *Compatible with Windows 2000, XP, and VISTA. Will require a purchased firmware upgrade to your XP2i gauge. See the options tab for part numbers to order.

|

|

| nVision Digital Test Gauge - Pressure accuracy to 0.025% of reading

- Field-replaceable modules: pressure, temperature, current, and voltage

- Temperature compensation from -20°C to 50°C

- ATEX/IECEx intrinsically safe

- Log and display 500,000 points at up to 10 readings/sec on up to two modules simultaneously

- IP67 (1-meter submersion for 30 minutes)

- Uses our new CPF hose and fitting system (leak-free and finger-tight to 10K PSI)

- Interactive real-time graphing of measurements

|

| Measuring instruments like pressure gauges and thermometers play an important role in the water and wastewater industries, providing key information about system status and allowing operators to make informed decisions about system operation and maintenance. Operators can guarantee that their water and wastewater systems are operating efficiently, safely, and ethically by selecting the right gauge and properly maintaining it. Floyd Australia is Here to Help No matter what your requirement is, at Floyd Australia, we can help you find the best solution. For more information on our range of water pressure gauges, please don’t hesitate to contact us.

|